Battery BMS, Functions and How Battery Management Systems Work. Lithium type batteries are usually structured to produce the desired voltage and capacity. Since the average voltage of a lithium battery is 3.7V, a 3S (in series) arrangement is required to produce 12V.

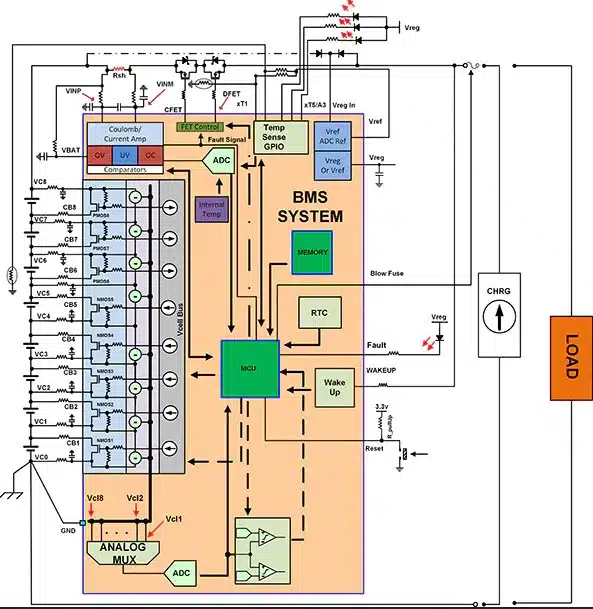

So that the voltage and current of this battery arrangement can be balanced, a system that can regulate it is needed, which is called BMS. So a battery management system (BMS) is a device used for balancing, monitoring and protecting batteries that are arranged in series or stacked batteries. BMS is equipped with passive cell balancing , voltage sensor for each battery, current sensor, temperature sensor, protection circuit to cut off the current.

The results of the study show that the BMS is able to read the battery voltage value with the largest error of 4.59%, the current value with an error of 2.002% and the temperature value with an error of 0.83%. Passive cell balancing can transfer energy and the ΔV of the battery has decreased to a value from 0.17 V to 0.14 V. The protection circuit can break the stacked battery circuit when conditions are overcurrent , overheat , undervoltage and overvoltage . Overheat reading error is 20 °C and undervoltage is 0.3 V

A battery management system (BMS) is a technology system that functions to maximize the life of a battery pack. It is highly recommended that all battery-powered PLTS electric vehicles or battery banks be installed with BMS.

The goal is to ensure the battery stays within its ideal working parameters. Some battery chemistries (such as lead acid) are fairly tolerant of abuse, but lithium and NiMH can both be damaged irreversibly by a single incident of misuse such as overcharging , over -discharging , or overheating.

Functions and How the Battery BMS Works

Some of the special functions of the battery management system include:

- Charge balancing , to ensure all cells complete charging at the same time and then to prevent damage through overcharging.

- Active balancing, in which energy is shifted from the stronger to the weaker cells, to ensure that all cells reach their point of maximum discharge at the same time.

- Temperature monitoring ( temperature monitoring ), to avoid damage due to overheating.

- Low -voltage cut-off , a way to isolate a battery when any cell reaches the minimum recommended voltage, and to prevent damage from over-discharging.

- State of charge (SOC) monitoring of all battery cells for electric cars. Through monitoring the voltage and current, the remaining capacity of each cell can be calculated.

Also Read: Battery Pack Composition Components (Battery Pack Module)

BMS also provides protection during charging and discharging; The BMS decides if the set limit is exceeded or if a failure occurs. The established BMS standards are the SMBus (System Management Bus) which is used for most portable applications, as well as the simpler CAN Bus (Controller Area Network) and LIN Bus (Local Interconnect Network) for battery pack use.

Keywords:

Battery Bms protection pdf, bms 3s 40a functions, how does bms work, bms function, battery bms function, charge BMS function, use of bms battery, laptop battery bms scheme