Electric motor components – Have you ever noticed a blender, or a fan. Why these components can rotate? If you are curious, don’t worry, because this time we will discuss the working principles and components of electric motors and their functions.

In the world of electronics, electric motors are components that cannot be separated. This also applies to the automotive world. Electric motors can not be separated in a car or motorcycle. Examples of the use of electric motors in cars, you can see in the starter system , Cooling Fan , and power windows.

While in general, electric motors will be very easy for us to meet in everyday life. For example fans, water pumps, washing machines and blenders. So do you know why these objects can rotate?

Definition of Electric Motors

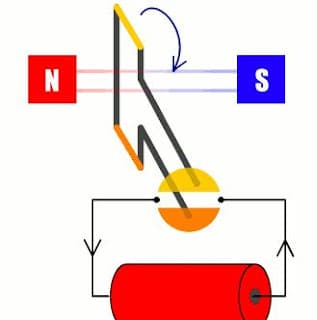

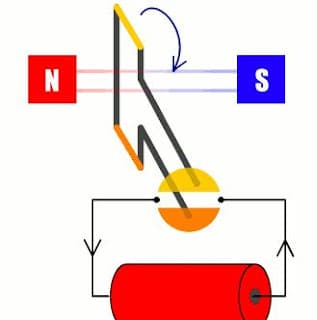

Quoted from wikipedia, an electric motor is a device that functions to convert electrical energy into motion energy. This tool is a dynamic electric tool because it produces movement. The working principle of an electric motor is to utilize magnetic attraction.

We certainly understand, when two magnets with the same poles are brought closer, these two magnets will move away. Conversely, if the magnetic poles are different, they will attract each other. This principle is the basis of electric motors.

when a bar magnet is placed in a magnetic field it will produce movement on the bar magnet. The rod, the magnet is placed on a shaft with a circuit in such a way that it can produce rotary motion when these two components interact.

Electric Motor Components

1. Stator Coil

2. Rotor Coil

3. Main Shaft

4. Brush

5. Bearing

6. Drive Pulley

7. Motor Housing

Functions of Each Section

1. Stator/Armature Coil

The stator is the main component of an electric motor. Because this component will be in direct contact with the performance of the motor. The stator is a static copper winding located around the main shaft. The function of the stator is to generate a magnetic field around the rotor.

This component consists of iron plates wrapped around copper. This copper is connected to a current source. So that when the winding is electrified, it will cause magnetism in the stator. In a motor generally has three stator coils. This depends on the capacity of the motor itself of course. The more the number of coils, the greater the magnetism produced. This of course will affect the speed of the motor.

However, for mini-sized electric motors, generally they only complement the stator using permanent magnets. So that the current used is also lighter. So, can permanent magnets be used in large-power electric motors? of course you can, but the resulting rounds tend to be small. That is why the magnetic coil is the choice so that the output is also satisfactory.

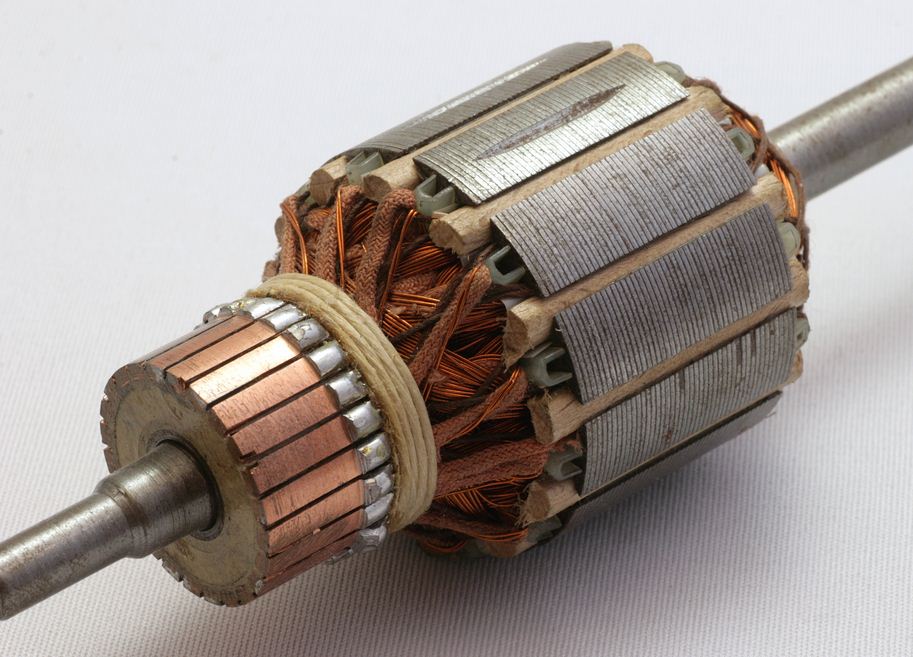

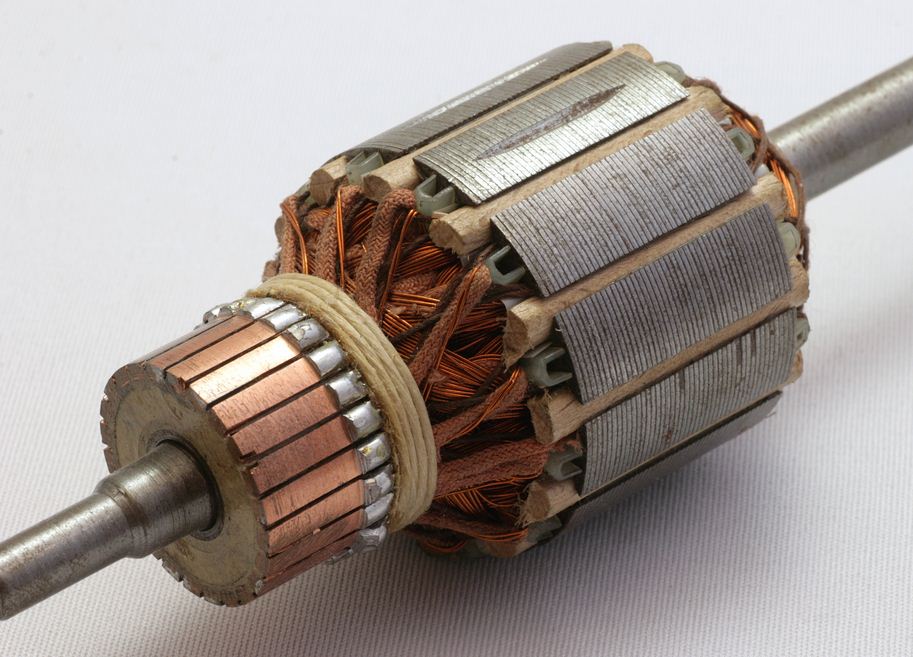

2. Rotor Coil/Commutator

This section also resembles the stator, except that the rotor is a dynamic copper coil. Why is it dynamic? Because this winding is attached to the main shaft or main shaft of the motor which will rotate.

as with the stator coil, the more the number of turns on the rotor, the greater the resulting rotation. Generally used copper with a small diameter. This is intended so that the number of turns is more even though it requires a large wire length.

end of the winding will be connected to another rotor which is located at the end of the main shaft.

3.Main Shaft

The main shaft is a metal component that extends as a place to attach several components. In addition to the coil rotor, the component attached to this shaft is the drive pulley. Generally the main shaft is made of aluminum which is anti-rust. In addition, this component must also be stable at high rotation and temperature.

4. Brushes

Brush is a copper brush that will connect the electric current source with the rotor coil. This brush is attached to a small rotor which is located at the end of the main rotor. The friction that occurs will flow the current in the same direction even though the rotor rotates. So that the rotation can be synchronous and continuous.

This friction will be supported by a spring that is located behind the copper brushes. This spring will always press the brush so that the brush will always stick to the rotor even though it rotates at high RPM.

In a motor must be equipped with two brushes. This brush will supply current and mass for the coil rotor. In addition, this component is a popular cause that causes the electric motor to die. The scale that sticks to the surface of the brush will cause the flow of current to be obstructed. In addition, the condition of the brush, which is worn out due to constant friction, can also hinder the flow of current.

5. Bearings

Because this tool generates rotation, special components are needed to be used as bearings so that the rotation takes place smoothly. This is the function of the bearing, as a bearing between the shaft surface and the motor housing. Bearings are generally made of aluminum which has a light frictional force. So it doesn’t hinder the rotation of the motor.

6. Drive Pulleys

This component is located at the outer end of the main shaft. Its function is to transfer the rotation of the motor to other components. These components are generally in the form of gears or pulleys, which are ready to be connected to components that need to be driven by this motor.

7. Motor Housings

On the outside of the electric motor we will find an iron plate that is used to protect all the components of the electric motor. In addition, the motor housing also functions to protect us as users from very high rotor rotation.

Those are the ins and outs of the electric motor components and their respective functions. Hopefully it can add to our knowledge and hopefully useful